Achievement Journey

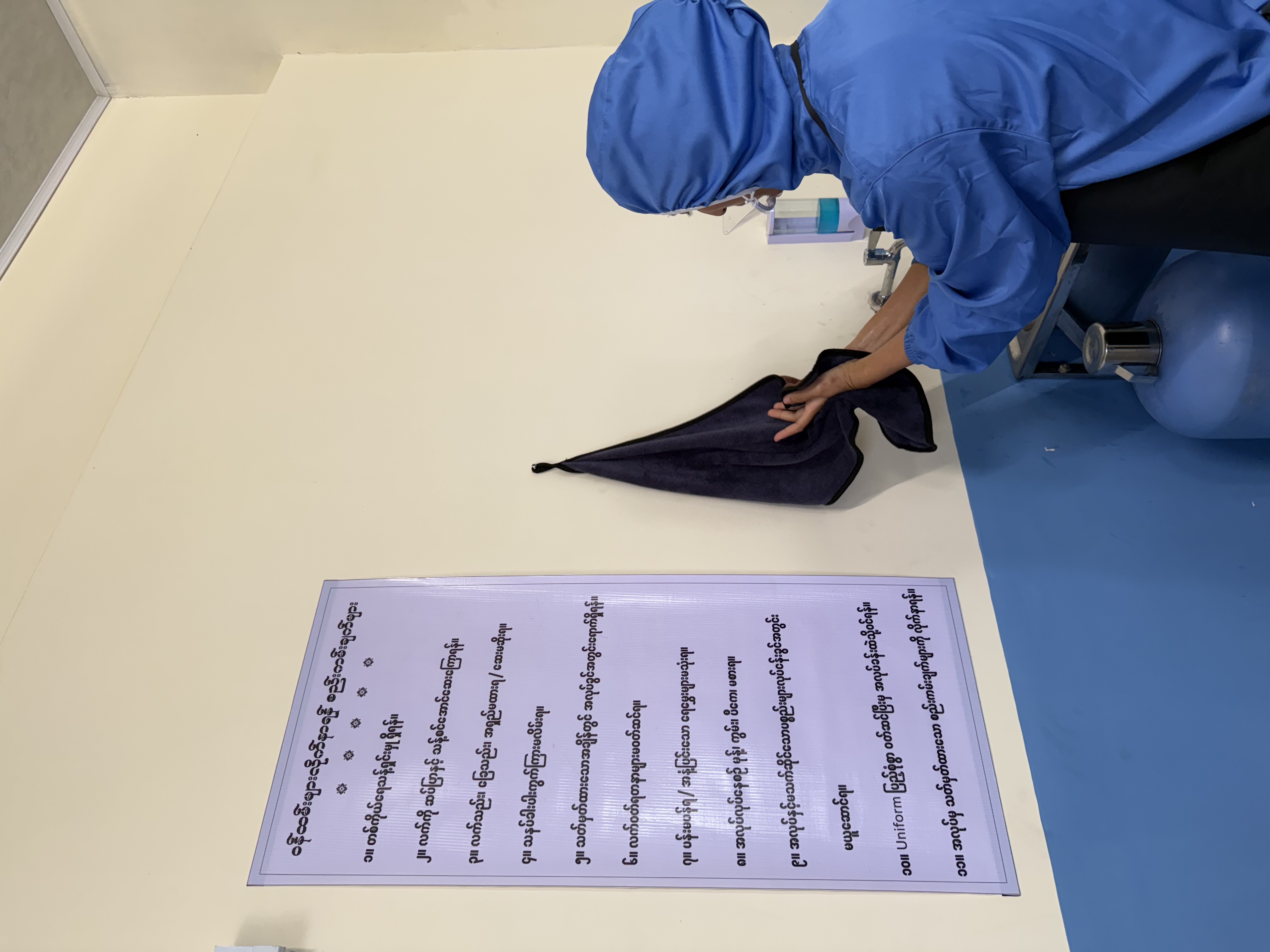

Customers gain confidence by seeing our operations first-hand. Site visits reveal our strict hygiene and food-safety practices that meet ISO 22000:2018 standards, proving our certification is a daily commitment to quality and trust.